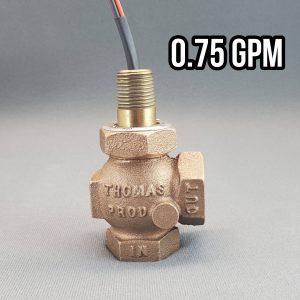

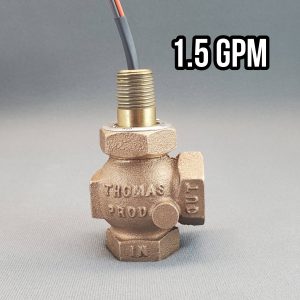

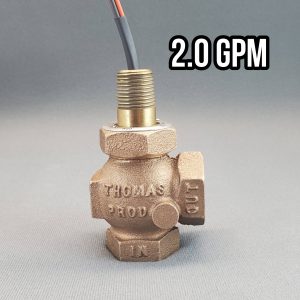

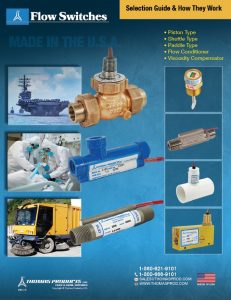

FLOW SWITCHES

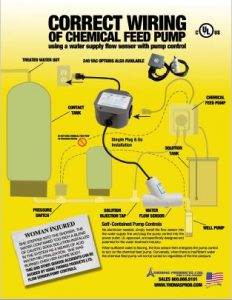

Flow switches are protection devices. Like flow sensors, they’ll warn you when flow rate is below or above the target range. Unlike flow sensors, though, flow switches initiate an action. They could turn on or shut down a pump, open or close a valve, or just light a warning bulb. How you use a flow switch is up to you.

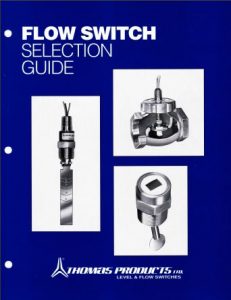

WATER FLOW SWITCH TYPES

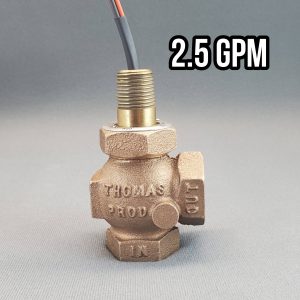

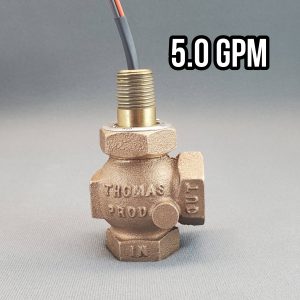

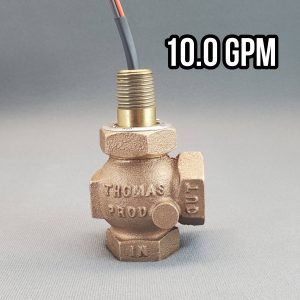

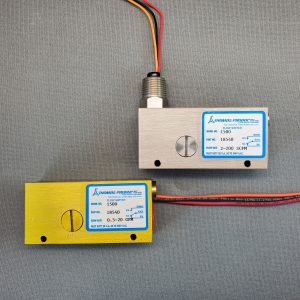

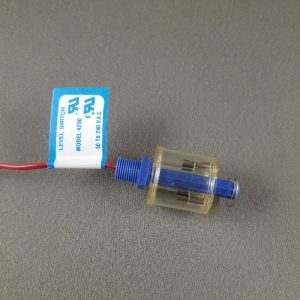

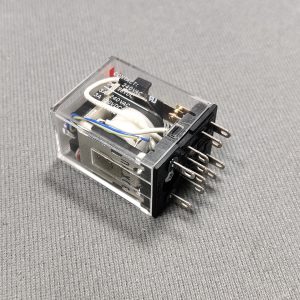

There are two main flow switch types — the paddle design and the piston or shuttle design. The paddle design of a flow switch places a hinged or spring-mounted paddle in the liquid flow path. Media flowing at the target rate holds this in position. An increase or reduction in flow moves the paddle, and this is sensed by a small switch. — Shuttle-type flow switches place a small cylinder or piston in the path of the moving liquid. Embedded in this piston is a permanent magnet. A switch outside the flow path senses the magnet’s position. If the magnet moves too far one way or the other, the switch activates an output signal. The flow rate that activates the switch is known as the “set point.”

FLOW SWITCH APPLICATIONS

Use flow switches to warn of liquid flow problems such as a blocked filter, failing pump or defective valve. Any of these malfunctions could affect process consistency, lead to equipment damage, and even cause spills and leaks. — Pump staging is another common application. A change in flow beyond the set point could be used to shut down a pump or bring a second unit online. Used this way, flow switches increase operational efficiency and reduce costs. — Every process with flowing liquid can benefit from flow switch controls. Food and beverage, pharmaceutical, water treatment and chemical production are just a few industries that use flowing liquids. Cooling systems are a good example. A change in flow will affect heat transfer rate and lead to damaged or defective product.

INVEST IN QUALITY PRODUCTS

Install fluid flow switches in your liquid handling process and, most of the time, you’ll never know they’re there. Yet, should a problem arise or the situation demand, they’ll spring into action. Flow switches protect equipment and people, guard against accidents, and help lower costs — but only if they work properly. — A poor-quality flow switch does more harm than good. It will either activate inconsistently — adding variability to your process along with annoying false alarms — or it will fail to work when needed. Avoid costly problems by investing only in high-quality flow switches from a trustworthy American manufacturer.

CATALOG OR CUSTOM

Flow switch applications are so numerous that it’s impossible to have one already engineered for every possible use. That’s why we offer custom design. Search our extensive product catalog for a flow switch meeting your needs. If none exists, let’s talk about a custom unit.

Recent Comments